Introduction

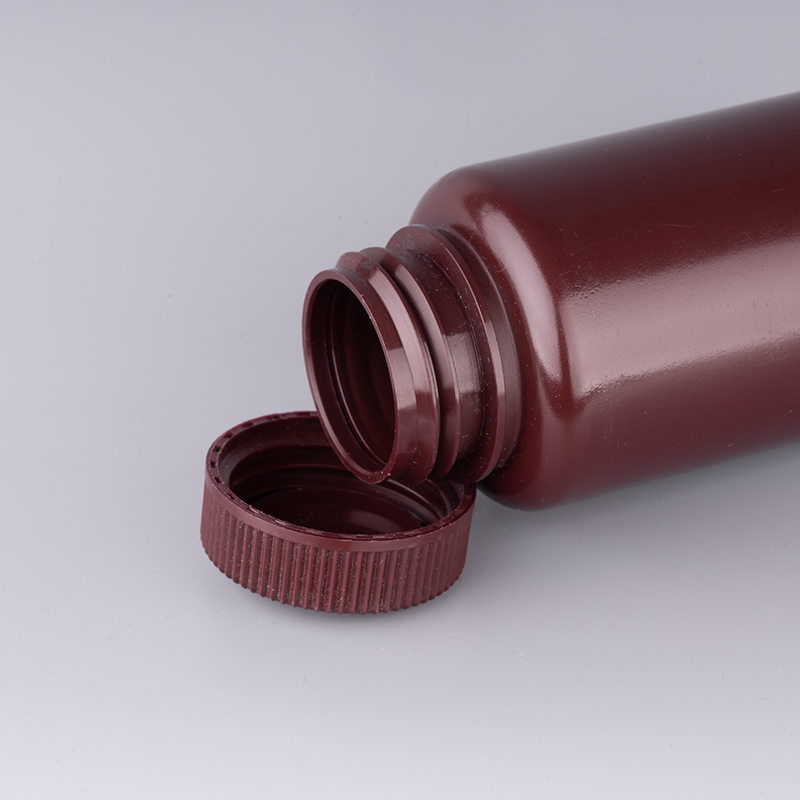

15 mL conical screw cap tubes are indispensable tools in laboratory settings, utilized for storage, centrifugation, and sample processing. The choice of materials used in manufacturing these tubes significantly influences their durability and suitability for diverse applications. Understanding the properties and characteristics of materials like Polypropylene (PP), Polycarbonate (PC), High-Density Polyethylene (HDPE), and others is crucial in discerning their impact on the functionality of these tubes.

Common Materials Used in Manufacturing 15 mL Conical Screw Cap Tubes

- Polypropylene (PP)

Polypropylene stands as one of the most common materials used in 15 mL conical screw cap tubes. Its chemical resistance, clarity, and affordability make it a preferred choice. PP's inherent properties render it suitable for various laboratory applications, from storing aqueous solutions to enduring centrifugation forces. However, while it offers excellent chemical resistance, it might not be suitable for some organic solvents due to permeability.

- Polycarbonate (PC)

Polycarbonate tubes possess high impact strength and transparency, making them ideal for certain applications requiring both durability and visibility. Despite their resilience, PC tubes might not be as chemically resistant as PP. They find application in scenarios where high visibility and robustness are essential, such as in sample observation.

- High-Density Polyethylene (HDPE)

HDPE, known for its high strength-to-density ratio and chemical resistance, finds usage in various industries. In 15 mL conical screw cap tubes, HDPE offers excellent chemical resistance but might lack the transparency of PP or PC. It is particularly suitable for long-term storage of samples but might not be appropriate for applications requiring high clarity.

- Comparison of Additional Materials

Other materials like polyethylene terephthalate (PET), fluoropolymers, and specialized blends are occasionally used in manufacturing tubes. PET offers good clarity but may not withstand extreme temperatures. Fluoropolymers exhibit superior chemical resistance but might be more expensive. Specialized blends often cater to specific applications, emphasizing particular characteristics like temperature resistance or chemical inertness.

Impact of Material Characteristics on Tube Durability and Suitability

- Chemical Resistance

The chemical resistance of 15 mL conical screw cap tubes is crucial in determining their durability and applicability across various laboratory tasks. Polypropylene (PP), known for its commendable chemical resistance, is suitable for a wide array of reagents commonly used in laboratories. However, it's important to note that certain aggressive solvents might have a limited impact on PP, leading to permeation or degradation over time. This factor restricts the use of PP tubes in scenarios involving specific organic solvents or concentrated acids.

Polycarbonate (PC), while offering remarkable impact strength and optical clarity, exhibits a different spectrum of chemical resistance compared to PP. PC tubes withstand a range of chemicals but may be susceptible to degradation in the presence of certain solvents, limiting their usage in applications involving aggressive chemicals.

High-Density Polyethylene (HDPE) showcases excellent chemical resistance, particularly against corrosive substances, oils, and greases. However, similar to PP and PC, HDPE might face limitations with certain solvents, necessitating careful consideration of its suitability for specific chemical environments.

- Temperature Stability

Temperature stability is another critical aspect influencing the suitability of 15 mL conical screw cap tubes for diverse laboratory applications. Polypropylene tubes generally possess moderate temperature resistance, making them suitable for standard laboratory procedures involving mild temperature variations. They perform well during routine centrifugation and storage at moderate temperatures but might not endure extreme heat or cold.

Polycarbonate tubes excel in temperature resistance compared to PP, demonstrating resilience against higher temperatures without deforming or losing their structural integrity. This attribute renders PC tubes suitable for experiments involving autoclaving, cryogenic storage, or applications where temperature fluctuations are frequent.

High-Density Polyethylene, while robust in various aspects, might have limitations in extreme temperature conditions. HDPE tubes could experience deformations or alterations in their physical properties under significant temperature variations, which need consideration when selecting tubes for specific experimental setups.

- Mechanical Strength

The mechanical strength of 15 mL conical screw cap tubes plays a pivotal role in their durability during centrifugation, handling, and transportation. Polycarbonate tubes boast exceptional impact resistance, making them suitable for applications where high mechanical strength is crucial. They withstand high-speed centrifugation and accidental impacts better than PP or HDPE tubes, ensuring sample integrity and minimizing the risk of tube breakage.

Polypropylene and High-Density Polyethylene tubes, although sturdy and commonly used, might not match the impact resistance offered by PC. However, they still maintain adequate structural integrity for routine laboratory procedures, handling, and moderate-speed centrifugation, providing cost-effective options for various applications.

Understanding the nuanced differences in chemical resistance, temperature stability, and mechanical strength among materials aids researchers and laboratory professionals in selecting the most suitable 15 mL conical screw cap tubes for their specific experimental requirements. These considerations ensure optimal performance and reliability while handling diverse laboratory tasks.

Advancements in materials science and engineering might lead to the development of hybrid materials or innovative manufacturing techniques, enhancing the overall performance and expanding the applicability of these tubes across a broader spectrum of laboratory procedures.

Conclusion

The selection of materials in manufacturing 15 mL conical screw cap tubes significantly influences their durability and suitability for various applications. Polypropylene, Polycarbonate, High-Density Polyethylene, and other materials offer distinct properties impacting chemical resistance, temperature stability, and mechanical strength. Understanding these material characteristics enables researchers and laboratory professionals to choose tubes best suited for their specific experimental requirements.

Future advancements in materials science might introduce novel compounds or modifications to existing materials, further enhancing tube performance and expanding their utility across diverse laboratory applications.

Related Products