Product Description:

Product parameters

SUN TRINE reagent bottles utilise high quality construction for lighter weight, lower bottle costs and factory-ready bulk packaging, with a variety of packaging options available.

2.material.

SUNTRINE reagent bottles are made of high quality polypropylene PP /high density polyethylene HDPE raw material,

non-biotoxic, produced in 100,000 grade cleanroom production environment, multiple quality system certifification.The sterilised plastic bottles are sterilised by electron beam irradiation and are ready for use, which greatly improves the packaging effiffifficiency of users.

3.Leak-proof liquid design.

SUNTRINE reagent bottles are designed to be leak-proof so that repeated opening and tightening will not affect the

sealing performance of the bottle, and the sealing ring inside the cap fits snugly against the bevelled inner edge of

the neck to form a leak-proof valve to ensure the cap is sealed.

4.Complete range of sizes.

SUNTRINE reagent bottles are available in a wide range of sizes from 8ML to 1000ML.

5.Uniform wall thickness, no wall hanging.

Uniform wall thickness, no wall hanging. SUNTRINE's world-leading moulding technology and manufacturing facilities

ensure that the reagent bottles have a more uniform wall thickness, high quality walls, a robust construction making

them suitable for any laboratory a PP lication and effective in preventing breakage or punctures, and a flat bottom which

is designed to run smoothly in the filling line.

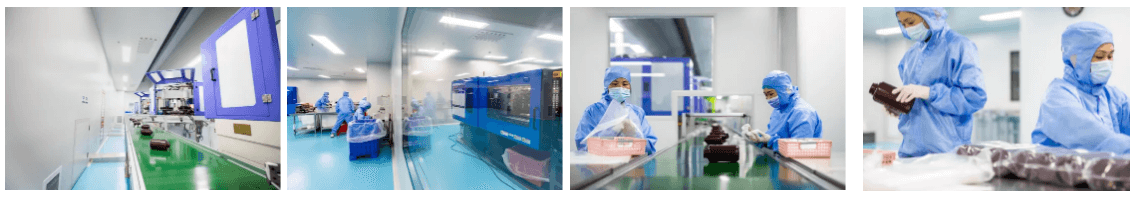

Process of production

step2. To the packaging workshop, the workers are checking whether the product is up to standard

step3. The workers are checking the products carefully to see if there is any problem

step4. Packaging and sealing after making sure the product is qualified